Spiral Staircases - Answers to Common Questions

If you’re wondering how to build a spiral staircase then this is the only guide that you’ll need!

If you’re wondering how to build a spiral staircase then this is the only guide that you’ll need!

In contrast to the straight staircases, the spiral takes your home aesthetics to the next level and is much more convenient for tight spaces such as halls, foyers, and kitchens. You can build a spiral staircase anywhere, as long as you follow the building code and all the maximum safety precautions.

To build a spiral staircase, you need to carefully plan out and measure the dimensions and then either purchase a compatible kit or build your own. To build your own spiral staircase you need specialized machinery and raw material, while purchasing a kit only requires careful application of the installation requirements.

Building a spiral staircase as a DIY project is an advanced improvement of your home and may turn out more challenging than expected. You would need assistance from a partner as well as careful measurement, kit selection, and a step-by-step orientation guide we’ve prepared for you.

How to Make a Spiral Staircase

Let’s go through the essentials first…

Analyzing the Spiral Staircase

There are a lot of different spiral staircase kits, including carefully produced steel or wood parts that fit together during construction. There is little to no room for error, so choosing the best kit for your home is one of the most important steps, deciding exactly how to fit a spiral staircase.

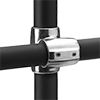

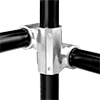

So, the spiral staircase kits involve a central pole, treads, spindles, and balusters and many of them also include hand railing pieces. Hence, to create a spiral staircase by yourself, you would need a machining tool and respective skill to replicate all the essential components for your DIY spiral staircase.

The most important piece in the spiral staircase is the center pole, which is the foundation and provides support for the entire spiral.

So, if you’re unsure whether you can produce the pieces by yourself, we recommend going with a pre-purchased spiral staircase kit.

Choosing a Spiral Staircase Kit

Spiral staircases cost between $1000 to $15,000, and even more, based on the materials of the stairs. Metal is the cheapest material for spirals and the most affordable option for most people, so if you wonder how to build a wooden spiral staircase, know that this is going to be expensive.

Wooden spiral staircase kits range from $5,000 and beyond, so if that’s not as per your budget, you can consider cheaper alternatives such as steel.

Additionally, if you don’t construct the spiral staircase yourself, a professional would charge you $40 up to 90$ per hour, for assembling a pre-purchased kit. So, if you want to minimize the cost, we recommend reading ahead to find out what you’ll need during the construction of your spiral.

Gathering Equipment and Tools

If you’re going to learn how to build a spiral staircase properly, you have to acquire and prepare the necessary tools beforehand. Even if you decide to go with a pre-purchased spiral staircase kit, without designing your own components, you’ll require a lot of your own tools and materials.

Here’s everything that you need to construct a spiral staircase:

- Hammer

- Drill

- Tape

- Screwdrivers

- Safety Glasses

- Ladder

- Drill bits

- Wrench

- Hacksaw

- Level Laser

- Lag Bolts

- Concrete Anchors

- Plump bob

Note: If you decide to build your own spiral staircase, you will need even more tools!

Meeting the Codes & Regulations

You may need to call your local permitting office for more information about the spiral staircase code and permits. The spiral staircases have a unique size and dimensions and significantly differ from the straight staircases, making it difficult to predict the local code’s permitted risers.

Here are some common dimensions for a spiral staircase:

| Wall and Pole Dimensions for Spiral Staircase | ||

| Size of Stairs | Size of Wall | Pole Positioning |

| 6 feet | 6 feet, 2 inches | 37 inches |

| 5 feet (6 inches) | 5 feet, 8 inches | 34 inches |

| 5 feet | 5 feet, 2 inches | 31 inches |

| 4 feet, 6 inches | 4 feet, 8 inches | 28 inches |

| 4 feet | 4 feet, 2 inches | 25 inches |

| 3 feet, 6 inches | 3 feet, 8 inches | 22 inches |

According to the national building code in the U.S., the minimum tread depth for a spiral is 7.5 inches. This means that your treads must be about 36 inches wide at about 7.5 inches depth.

That was how to make spiral staircase calculations and preparation, so let’s check the safety!

Safety Precautions & Preparation

If you’re wondering are spiral staircases safe, know that the construction is the most important factor. If built properly, spiral staircases can be strong and secure without you having to worry about carrying furniture, multiple people, or other weights you could expose your staircase to.

While in this guide we share all the common aspects shared by most spiral staircase kits, we strongly recommend closely following the safety instructions in the manual. Another piece of advice will be to purchase a spiral staircase kit from a reputable provider to avoid low-quality components.

How to Install Spiral Staircase Properly

Let’s next move on with the in-depth installation steps:

1. Measuring the Dimensions

Now that you have a rough idea of how to build spiral staircase, measuring and planning out the dimensions could be the most time-consuming part of the process.

So, let’s get the dimensions right!

Measuring the Wall & Height

The first step is to extend a measuring tape from the bottom of the ground level to the upper floor to get the correct length. This will help you determine exactly how tall your staircase will be, minding that if you have a carpet, you need to start measuring from the solid beneath the cover.

Planning the Spiral’s Layout

You should plan out a diameter of at least 26 inches for your spiral staircase as the wider the steps are the safer the staircase would be. Additionally, you should plan to add at least 2 inches (5 cm) to the overall diameter of the staircase to verify that you have an allowance for the handrail.

Calculating the Steps/Spaces

Continuing with the question “How do I build a spiral staircase?”, we cannot skip the calculation that will decide the craftsmanship of your treads.

So, when you have the height and spiral layout planned out, you need to divide the height of your spiral staircase by 7, which is the perfect raise between the treads. You should then round up that number and divide the height again by the number of steps to get the exact distance between them.

Example: For 96 inches in height, divide 96 by 7 to get 13.71 (14 steps), and then divide 96 by 14 to calculate the inches between each step.

Tip: We recommend sketching your plan on a piece of paper for easier orientation during the spiral staircase construction.

2. Installation of the Center Pole

The next step is to mark the location for the center pole by using a plumb bob from the upper floor to get the exact 90-degree angle. If you’re using a kit, you can now install the center pole by drilling holes and attaching a steel or wooden plate via concrete anchors to the ground floor.

In contrast, if you’re building your own spiral staircase, you need to cut a section of a steel pipe that is going to be your center pole. For cutting you can use a circular saw, with a carbon-steel blade dedicated for cutting metal.

If you’re going with a DIY spiral staircase, you need to also design your own plate, or you can purchase one, sized for your center pole. It’s very important to secure the plate to the concrete floor and verify that the base flange and the pole will support the weight of the spiral staircase.

With the foundation ready and secured, it’s time to learn how to build spiral stairs on your pole!

3. Adding the Treads (Stairs)

If you have a ready-to-install spiral staircase kit, you’re ready to slide in the treads, by having your partner waiting to soften the impact on the bottom. If you’re designing your own treads, you need to make sure that you have enough raw material and machinery to cut out the steps using the measurements you’ve made earlier.

We recommend using premade metal threads that are designed in accordance with the national building code, which will save you a lot of time and labor. Otherwise, you must learn how to make spiral stairs using dedicated machinery and create at least one or two extra just in case.

When you slide down the treads, it’s time to arrange them around the center in an overlapping manner. Remember that every next stair must be about 1 inch away from the previous tread, which will produce the spiral formation you're looking for.

Then, it’s time to secure the treads either using bolts or anchoring them to the center pole. Most spiral staircase kits also include premade alternating spaces to ensure all steps are the same distance apart.

Tip: With premade metal threads, you can always top them with a wooden cover!

4. Installing the Railing

The next step is learning how to install a spiral staircase handrail, which will add to the security of your spiral staircase. If you’re using a modular kit, you have the handrails ready to install, but if you’re making them yourself, you need a lot of sharpening and cutting.

Crafting handrails from scratch, especially for a custom-sized spiral staircase is the most difficult part, considering that you would need a flexible material. So, if you’re not a professional with access to specialized machinery, it’s best to purchase or order custom-sized handrails for your staircase.

5. Setting up the Balusters

If you want to add up to the fashion of your spiral staircase, you need to consider drilling holes in the outer ends of your treads. This will allow you to install stringers providing you with the opportunity to fit custom designed balusters of your choice.

Note: If you have a pre-made spiral staircase kit, you can simply screw the stringers into the already-designed holes and install your balusters.

How To Build a Wooden Spiral Staircase

If you want to build a wooden spiral staircase, you will need a lot of wood, from which you’ll need to cut out and design the three main components:

- The center pole

- The raisers

- The treads

That’s it. Let’s get into the construction of a wooden spiral staircase!

1. Shape your Center Pole

If you’re wondering how do you build a spiral staircase out of wood without a kit, the first step is measuring the height and shaping your wooden center pole.

You need to remember that the pole is holding the weight of everything, so you’re looking at a thick, at least 10 inches in diameter at the base. When you have your wooden center pole, it’s time to drill a hole in the floor to attach the plate or use wooden anchor bolts to attach the base of the center pole.

You need to repeat the same process for the upper floor and verify that the pole is securely attached on both sides, without wiggling.

2. Laying Out Your Spiral

Well, according to your planning and calculation, you should have a rough idea of how your steps must be laid out. So, mark where each step should be and drill holes for pegs, into the center pole, so you can attach the treads later.

That’s the easy part, but you need to be precise with drilling the holes, which must be at least 2 inches deep. When ready, you can design your pegs and hammer them into the center pole.

3. Trim the Wooden Treads

We’ve already described how to get the correct dimensions for your stair tread, so when you have the size, spacing, and height you can start trimming. As per your calculations, you need to cut out the exact number of treads, by having at least one or two extras, if you mess up something.

When you’re ready, you can fit the treads into the pegs and secure them using different ways such as screwing them or anchoring them. At this point, you’ll be able to climb the stairs up and down the spiral staircase without feeling wiggling.

That was how to build a spiral staircase out of wood, so we can now move on to the tweaking!

Quick Tip: You can use gouge to create a nice and smooth (no-slip) surface texture!

4. Install Handrails (Optional)

When you have your spiral staircase ready, you can order custom handrails and whether they are made of wood or other material, the price may vary. However, attaching the handrails to the wooden threads shouldn’t be a hard job, as you can use any conventional way of attaching them.

Once you’re done, you have many design options for handrails, which will add to your spiral staircase’s aesthetics.

That was how to make a wooden spiral staircase, so let’s next answer some arising questions!

How To Get Furniture Up a Spiral Staircase When Needed

If your spiral staircase is securely installed and there is no wiggling, you can get your furniture up and down without any worries.

If your spiral staircase is securely installed and there is no wiggling, you can get your furniture up and down without any worries.

The most important thing is to have a partner who will help you out with rotating the piece of furniture, considering the tight space that spiral staircases occupy.

If you’re wondering how do you get furniture up a spiral staircase, know that this happens with a lot of turns and maneuvers.

If you’re alone, you’ll probably fail in attempting to take your sofa upstairs using a spiral staircase, but with a helping pair of hands, there is nothing to worry about.

One moves furniture upstairs and the other helper supports the weight from the bottom.

If there is one general tip you can benefit from, is to go slowly and release the weight on every thread for grip re-adjustment and thoughtfully planning the next move.

This is pretty much how to get furniture up spiral staircase in the easiest way possible, but again, use a helping hand!

Are Spiral Staircases Safe

Spiral staircases are completely safe as long as the central pole is secure. If you notice that the center pole’s plate has been detached, something is moving unpredictably, or weird noises are coming out, you may need to consider straightening up the contraption.

Again, the center column holds the entire weight of the spiral staircase, so we recommend closely inspecting the lower and upper base. Whether it’s wooden, metal, or steel, you need to check the installation every now and then and make sure that the central pole is strong and doesn’t move.

Interesting Fact: Why Did Early Fire Stations Have Spiral Staircases?

The reason why early fire stations had spiral staircases, is to prevent wayward horses from wandering upstairs. One day, during a fire call, a firefighter went to the ground floor solely by using the pole, (without touching the steps), which made them question why not leave the pole permanently there.

So, nearly two decades later, in contrast to the horses, fire poles still remain in fire departments to this day. This is because it was discovered that this is a very convenient way to get from the sleeping quarters to the ground floor and fire engines in an instant.

Wrapping Up

So, in this guide, we’ve learned how to build a spiral staircase!

You now know that you can either purchase a spiral staircase kit, or build your own by creating a center pole, treads, and handrails. Fortunately, with the right tools, machinery, and expertise you can achieve high-quality results, solely by reading the complete instructions in the guide above.

We hope this guide was helpful so follow us for more!